Product overview

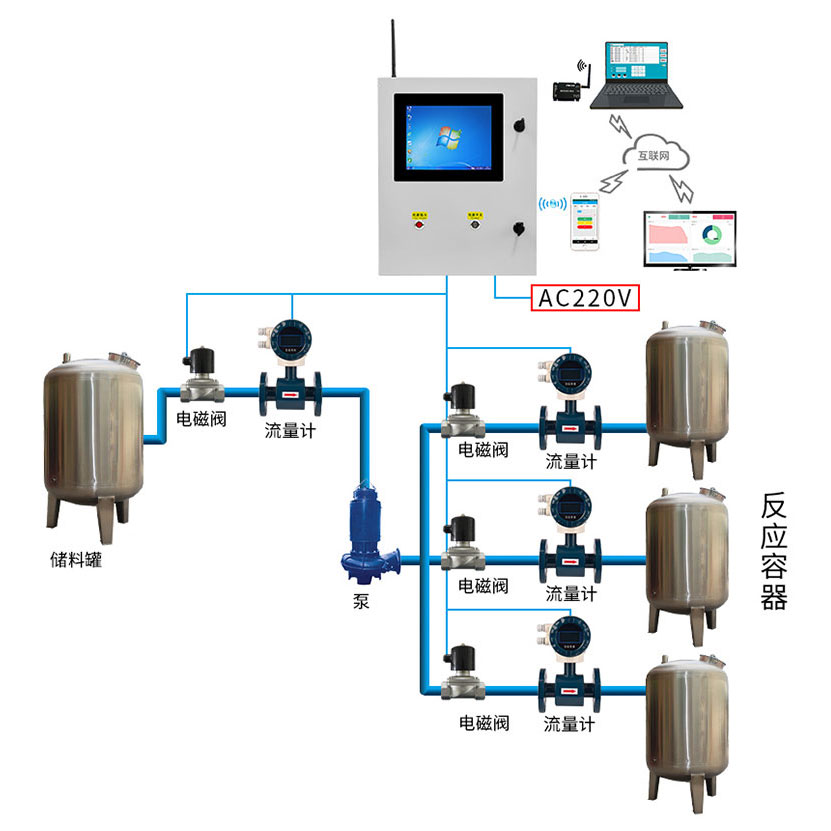

The GER intelligent quantitative control system consists of flow sensor, flow quantitative controller, solenoid valve and distribution box. According to the pulse flow signal reported by the flowmeter to the quantitative flow controller, when the cumulative flow reaches to the set value (quantitative value), the quantitative controller will send a switching signal to the solenoid valve or pump, and the startup and shutdown control of valves and pumps has been achieved. It's characterized by simple and easily learnt operation, intuitive display and combination of manual or automatic flow control. It's specially applicable to oil field oil blending, watering, dusting power drug, burdening, quantitative water injection and quantitative control of various liquids.

Product features

● Measuring medium: Liquid, gas and steam;

● Quantitative range 0.1-999999 litres;

● Maximum value of instrument constant that can be placed: 999999 times/litre;

● Providing the sensor and transmitter with 12VDC and 50mA power supply;

● Working environment and conditions: 0-45℃, relative humidity<85%;

● Power supply: AC220V;

● Display of total accumulation by 11-digit LCD and display of instantaneous value by 4-digit LCD;

● Boundary dimension of intelligent quantitative controller: 160*80*140mm;

● The large and small valve control is set to control large flow and small flow, respectively to achieve accurate quantitative control;

● When the pump and valve are controlled at the same time, the function of pump delay starting and pump valve closing in advance is set;

● It's equipped with material overflow and pump suppression interface. When the material overflow and pump suppression happens, ramming material should be disabled for real-time protection;

● The total accumulation, instantaneous flow, time, flowmeter input signal value, etc. can be viewed via quantitative controller, and the inquiry function of number of times of ramming material, time of ramming material each time, quantity of ramming material each time and daily or monthly accumulation is set;

● It can be equipped with printer for real-time printing function, and the printing function covers beginning and ending time of ramming material, quantity of ramming material, actual quantity of ramming material and name of ramming material (freely set according to customer requirements); The working state before ramming material is kept in case of outage;

● The controller and control cabinet is subject to complete independent research and development, thus we can customize other functions if needed;

● Only flowmeter, control box and cutoff equipment are required with simple structure and low cost;

● The control circuits and components in the control cabinet are customized pursuant to flowmeter and equipment required by the customer, the signal line is connected simply, and the flowmeter and cutoff equipment are subject to direct power supply in the control cabinet without adjustment required generally after arriving at the site;

● The controller is of Chinese display with convenient operation and intuitive display; The control cabinet panel is set with "Start", "Stop" and "Clear" buttons and connected to external buttons with display of "status indicator lamp", thus the display is intuitive and the operation is simple, convenient and easy to learn;

● The quantitative control value each time can be changed at will according to the need which can be completed within the quantitative controller, several groups of usual doses can be set as required. At the moment of ramming material, direct selection should be conducted without resetting;

● The total accumulation, instrument constant and previous quantitative value are subject to power down protection, and the protection time exceeds 10 years. The warranty period is 12 months.

Product model selection

GER | Intelligent quantitative control system | ||

***(100 indicates DN100 nominal diameter) | ***(10 indicates the PN1.0Mpa nominal pressure) | Flow range (m3/h) | |

4 | The sensor of pipe diameter is subject to threaded connection (customizable), front and rear straight pipe sections and filters are equipped and the maximum pressure is 63MPa | 0.04~0.25 | |

6 | 0.1-0.6 | ||

10 | 0.2~1.2 | ||

15 | The pressure pipe diameter standard configuration is subject to threaded connection (customizable), the pressure is 2.5MPa and the maximum pressure is 32MPa | 0.6~6 | |

20 | 0.8-8 | ||

25 | 1~10 | ||

32 | 1.5~15 | ||

40 | 2~20 | ||

50 | The sensor of pipe diameter is subject to flange connection (customizable), the pressure is 1.6MPa and the high pressure should be customized | 4~40 | |

65 | 7~70 | ||

80 | 10~100 | ||

100 | 20~200 | ||

125 | 25~250 | ||

150 | 30~300 | ||

200 | 80~800 | ||

GER- | |||

* User notes

The sensor should be far away from the external magnetic field. In case of failure in avoidance, necessary measures should be taken. To avoid the influence of normal liquid delivery when repair, the by-pass line should be installed outside the straight pipe on both ends of the sensor. When the sensor is of outdoor installation, the water repellent treatment of amplifier plug should be completed. The instrument is of flange, thread and quick-clamp connection.

QQ客服

QQ客服