Product overview

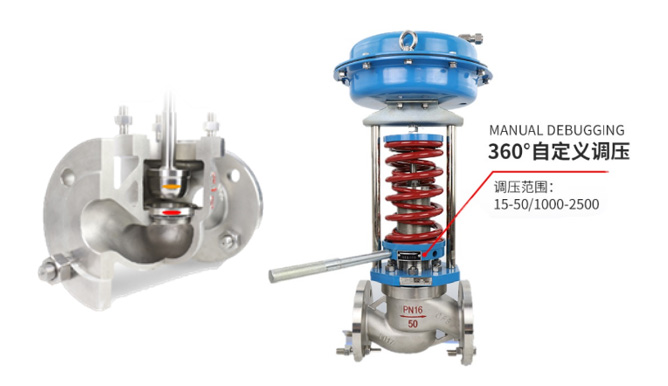

No external energy is required by the VPZ self-contained pressure regulator. The energy of the adjusted medium is used as the power source for introduction into actuator control valve element position with pressure difference and flow rate at both ends changed and upstream (downstream) pressure stabilized. The self-contained pressure regulator has the advantages (such as sensitive action, good leakproofness and small pressure set point undulation force) and is widely used for gas, liquid and medium pressure stabilization or decompression/pressure stabilization automatic control. The valve body caliber scope is DN20~300 and the pressure segmented regulation is 15~2500Kpa.

Product features

● No external energy is needed, and it can work in the place without electricity or gas which is convenient and saves energy.

● The pressure section range is fine and intersecting with high regulation precision;

● The pressure setting value can be set continuously during the operation period.

● The downstream pressure is adjusted and the ratio of upstream pressure to downstream pressure can be 10:1~10:8;

● Rubber diaphragm test, high actuator test precision and sensitive action;

● The pressure balance mechanism is used, making the control valve react sensitively with accurate control.

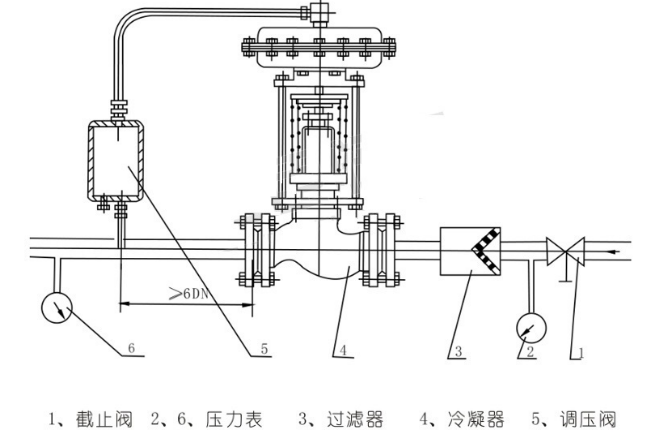

Product application

No external energy is required by the self-contained pressure regulator which is of small volume, simple structure and convenient repair, can work in the place without electricity or gas, is convenient and saves energy, and is widely used for the industries, such as petroleum, chemical engineering, papermaking, power generation and lithium battery new energy.

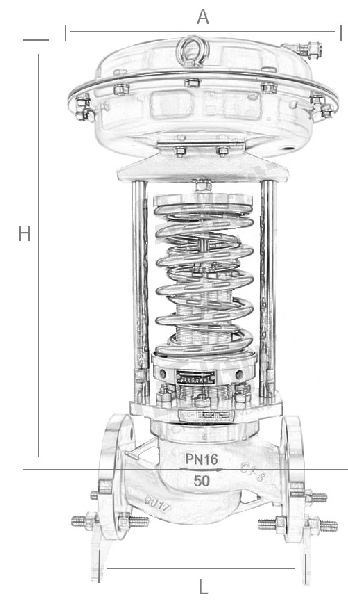

Control valve size

Control valve size

Nominal diameter (DN) | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | ||

Flange adapter tube size (B) | 383 | 512 | 603 | 862 | 1023 | 1380 | 1800 | 2000 | 2200 | ||||||

Space between flange ends (L) | 150 | 160 | 180 | 200 | 230 | 290 | 310 | 350 | 400 | 480 | 600 | 730 | 850 | ||

Pressure regulating range (KPa) | 15-140 | H | 475 | 520 | 540 | 710 | 780 | 840 | 880 | 915 | 940 | 1000 | |||

A | 280 | 308 | |||||||||||||

200-500 | H | 455 | 500 | 520 | 690 | 760 | 800 | 870 | 880 | 900 | 950 | ||||

A | 230 | ||||||||||||||

120-300 | H | 450 | 490 | 510 | 680 | 750 | 790 | 860 | 870 | 890 | 940 | ||||

A | 176 | 194 | 280 | ||||||||||||

480-1000 | H | 445 | 480 | 670 | 740 | 780 | 850 | 860 | 880 | 930 | |||||

A | 176 | 194 | 280 | ||||||||||||

600-1500 | H | 445 | 570 | 600 | 820 | 890 | 950 | 1000 | 1100 | 1200 | |||||

A | 85 | 96 | |||||||||||||

1000-2500 | H | 445 | 570 | 600 | 820 | 980 | 950 | 1000 | 1100 | 1200 | |||||

A | 85 | 96 | |||||||||||||

Approximate weight (Kg) | 26 | 37 | 42 | 72 | 90 | 114 | 130 | 144 | 180 | 200 | 250 | ||||

Connecting pipe interface thread | M16X1.5 | ||||||||||||||

Technical parameters

Nominal diameter DN | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | |

Rated flow coefficient Kv | 7 | 11 | 20 | 30 | 48 | 75 | 120 | 190 | 300 | 480 | 760 | 1100 | 1750 | |

Noise measurement coefficient Z value | 0.6 | 0.6 | 0.6 | 0.55 | 0.55 | 0.5 | 0.5 | 0.45 | 0.4 | 0.35 | 0.3 | 0.2 | 0.2 | |

Allowable pressure differential (Mpa) | PN16 | 1.6 | 1.5 | 1.2 | 1,0 | |||||||||

PN40 | 2.0 | |||||||||||||

Valve deck form | Standard form -17~+300℃ and high-temperature type +300℃~+450℃ | |||||||||||||

Gland type | Bolt compression type | |||||||||||||

Gland packing | V-shaped teflon packing, asbestos packing containing immersed teflon, asbestos textile packing and graphite packing | |||||||||||||

Valve element form | Single seat and sleeve valve element | |||||||||||||

Flow characteristics | Linearity | |||||||||||||

Actuator parameter

Effective area (cm) | 32 | 80 | 250 | 630 |

Pressure setting range (MPa) | 0.8~1.6 | 0.1~0.6 | 0.015~0.15 | 0.005~0.035 |

0.3~1.2 | 0.05~0.3 | 0.01~0.07 | ||

Smaller differential pressure for ensuring the normal operation of the pressure valve △Pmin(MPa) | ≥0.05 | ≥0.04 | ≥0.01 | ≥0.005 |

Allowing greater pressure difference between upper and lower membrane chambers (MPa) | 2.0 | 1.25 | 0.4 | 0.15 |

Material | Membrane cover: Steel plate galvanization; Diaphragm: EPDM or FKM with fiber | |||

Control line and contact | Copper pipe or steel tube 10×1; Ferrule-type contact: R1/4" | |||

Note: ※ The pressure setting range corresponding to the effective area isn't applicable to DN150-250. | ||||

Performance index

Set value deviation | ±8% | |||

Allowable leak amount (Under the specified test conditions) | Hard seal | 4×0.01% rated valve capacity | ||

Soft seal | DN15~50 | DN65~125 | DN150~250 | |

10 bubbles/min | 20 bubbles/min | 40 bubbles/min | ||

Control valve material

Code of material | C (WCB) | P (304) | R (316) | |

Main parts | Valve body | WCB (ZG230-450) | ZG1Cr18Ni9Ti (304) | ZG1Cr18Ni12Mo2Ti (316) |

Valve element and valve seat | 1Cr18Ni9Ti (304) | 1Cr18Ni9Ti (304) | 1Cr18Ni12Mo2Ti (316) | |

Valve rod | 1Cr18Ni9Ti | 1Cr18Ni9Ti | 1Cr18Ni12Mo2Ti | |

Diaphragm | NBR, EPR, chloroprene rubber adhesive and oil resistant rubber | |||

Membrane cover | A3 and A4 steel applied with tetrafluoroethylene | |||

Packing | Teflon and flexible graphite | |||

Spring | 60Si2Mn | |||

Guide sleeve | HPb59-1 | |||

QQ客服

QQ客服