Product overview

The VPS pneumatic control valve consists of adjustable bolt, actuator box, crank arm, cylinder block, cylinder shaft, piston, connecting rod and universal shaft. It's a right-angle rotation structure and used with valve positioner and can realize the proportional control; The V-shaped valve element is the most applicable to various adjustment occasions with large rated flow coefficient, large adjustable ratio, good sealing effect, flexible regulation performance and small volume and subject to vertical and horizontal installation. It applies to the control of such media as gas, steam and liquid. It's one of the important instruments for industrial process control widely used by the industrial enterprises (such as petroleum, chemical engineering, electric power, metallurgy and lithium battery new energy).

Product features

● Large rated flow coefficient and adjustable ratio and good sealing effect;

● Sensitive regulation performance, small volume and vertical and horizontal installation;

● Double bearing structure, small break-out torque, good sensitivity and induction speed, and super strong shear capacity.

● Simple control, quick response, essential safety and no explosion precautions needed, separately.

● The corresponding thrusting force is produced as per the control signal pressure to rush and adjust the mechanism action

● Convenient installation and repair.

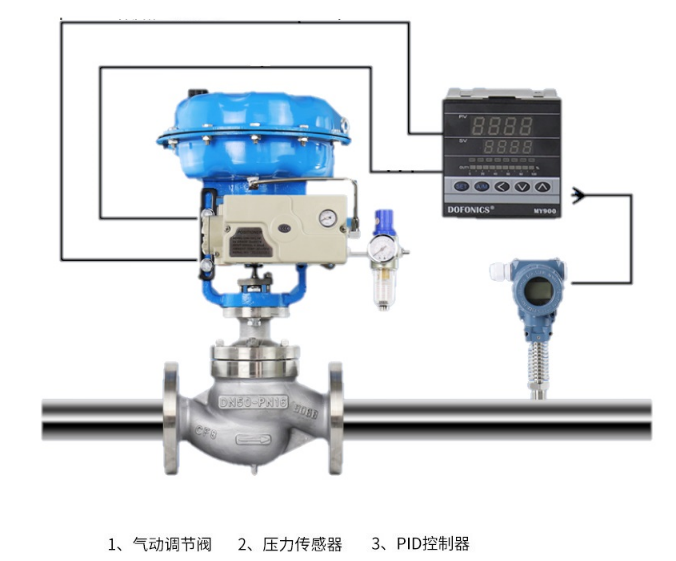

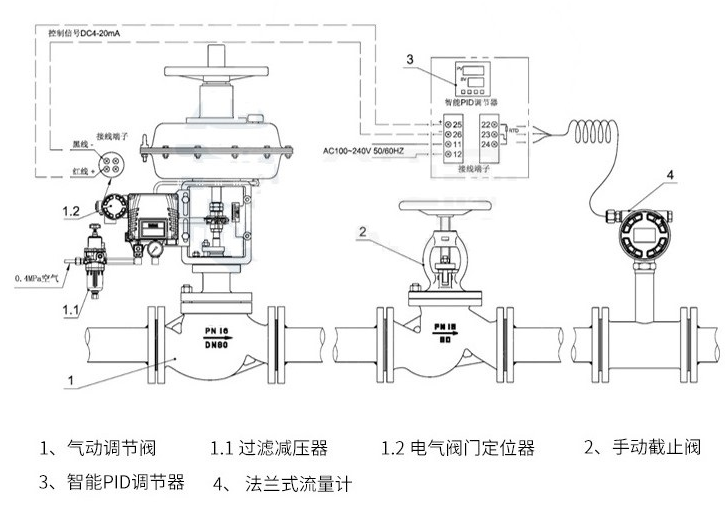

Product application

Technical parameters

Nominal diameter (DN) | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | |

Valve seat diameter (dn) | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | |

Rated flow coefficient(KV) | Single seat | 6.9 | 11 | 17.6 | 27.5 | 44 | 69 | 110 | 176 | 275 | 440 | 630 | 875 | 1250 |

Sleeve | 6.3 | 10 | 16 | 25 | 40 | 63 | 100 | 160 | 250 | 360 | 570 | 850 | 1180 | |

Allowable pressure differential (MPa) | Single seat | 3.8 | 3.2 | 3.0 | 2.0 | 1.8 | 1.5 | 1.4 | 1.0 | 0,7 | 0.6 | 0.5 | 0.3 | 0.1 |

Sleeve | 6.4 | 6.4 | 5.2 | 5.2 | 4.6 | 4.6 | 3.7 | 3.7 | 3.5 | 3.1 | 3.1 | 2.6 | 2.2 | |

Nominal pressure (MPa) | 1.6, 2.5, 4.0, 6.4 and 10.0 | |||||||||||||

Rated travel (mm) | 16 | 25 | 40 | 60 | 100 | |||||||||

Actuator model | PHA220 | PHA230 | PHA340 | PHA450 | PHA560 | |||||||||

Valve deck form | Standard type (-17~+250℃), high-temperature type (+250~+450℃), low-temperature type (-40~-196℃) and corrugated pipe sealing type (-40~+350℃) | |||||||||||||

Gland form | Bolt compression type | |||||||||||||

Gland packing | V-shaped polytetrafluoroethylene packing and V-shaped flexible graphite packing | |||||||||||||

Valve element form | Single seat type and sleeve type | |||||||||||||

Flow characteristics | Equal percent and linearity | |||||||||||||

Actuator

Category of actuator configured | PHA multiple spring film actuator | ||||

Actuator model | PHA220 | PHA230 | PHA340 | PHA450 | PHA560 |

Effective area (cm2) | 350 | 350 | 560 | 900 | 1400 |

Travel (mm) | 10 and 16 | 24 | 40 | 40 and 60 | 100 |

Spring range (KPa) | 20~100 (standard), 20-60, 60-100, 40-200 and 80-240 | ||||

Diaphragm material | Nitrile rubber with nylon cloth and ethylene propylene rubber with nylon cloth | ||||

Gas supply pressure | 140~400KPa | ||||

Air source port | RC1/4" | ||||

Ambient temperature | -30~+70℃ | ||||

Accessories available | Locator, air filtering pressure reducer, lock-up valve, travel switch, valve position transmitter and handwheel | ||||

Acting form | Air-to-close type (B)-the valve is opened when gas leakage (FO); Air-to-open type (K)-the valve is closed when gas leakage (FC) | ||||

Performance index

Item | Without locator | With locator | ||

Intrinsic error % | ±5.0 | ±1.0 | ||

Return difference % | 3.0 | 1.0 | ||

Dead zone % | 3.0 | 0.4 | ||

Starting/ending point deviation % | Air-to-open type | Starting point | ±2.5 | ±1.0 |

Starting point | ±5.0 | ±1.0 | ||

Air-to-close type | Starting point | ±5.0 | ±1.0 | |

Ending point | ±2.5 | ±1.0 | ||

Rated travel deviation % | ≤2.5 | |||

Leak amount L/h | 0.01%×rated valve capacity | |||

Adjustable range R | 30: 1 | |||

Control valve material

1 | Valve body | WCB | 304 | 316 | 316L |

2 | Gasket | Graphite gasket | Graphite gasket | Graphite gasket | Graphite gasket |

3 | Valve seat/sleeve | 304 | 304 | 316 | 316L |

4 | Valve element | 304 | 304 | 316 | 316L |

5 | Guide sleeve/cap | 304 | 304 | 316 | 316L |

6 | Arolium | Graphite gasket | Graphite gasket | Graphite gasket | Graphite gasket |

7 | Bonnet | WCB | 304 | 316 | 316L |

8 | Valve rod | 304 | 304 | 316 | 316L |

9 | Metal pad | 304 | 304 | 316 | 316L |

10 | Packing | PTFE/graphite | PTFE/graphite | PTFE/graphite | PTFE/graphite |

11 | Bolt | 25 | Stainless steel | Stainless steel | Stainless steel |

12 | Packing gland | WCB | 304 | 316 | 316L |

QQ客服

QQ客服