Product overview

The FTE intelligent electromagnetic flowmeter is a fluid measuring instrument developed and produced by the advanced technology and characterized by high precision and reliability and long service life. To ensure the product quality, our company carries out detailed study and control of each link in the processes (such as product structure, material selection, manufacturing process, production and assembly and ex-factory test) and equip complete flow calibration and detection system. To adapt to the needs of the measurement site, the high pressure electromagnetic flowmeter system and plug-in electromagnetic flowmeter system have been developed, especially the plug-in electromagnetic flowmeter is of good economy, timeliness and stability when used for the large diameter piping system. The online installation type can be installed and repaired without shutdown and is used easily. As a result, our company's electromagnetic flowmeter system is suitable for all fields, such as petroleum, chemical engineering, thermal power generation, lithium battery new energy, metallurgy, food, environmental protection and hydraulic engineering.

Product features

● There is no baffle in the electromagnetic flowmeter without pressure loss or fluid blocking almost. There is no mechanical inertia, but rapid response, wide flow measurement range (flow velocity: 0.3~12m/s) and good stability. It can be used for automatic detection, adjustment and program control system.

● It's used for measuring the liquid whose conductivity exceeds 5uS/cm without influence of fluid density, viscosity, temperature, pressure and conductivity change. The sensor induced voltage signal has a linear relationship with the average velocity, and the measurement accuracy is high.

● Accuracy grade: Level 0.2, 0.5, 1.0 and 1.5. Meet the demands of different users.

● As for the sensor part, only the lining and electrode are in contact with the liquid under test. As long as the appropriate electrode and lining material is chosen, the resistance to corrosion and wear can be realized. The electromagnetic flowmeter is divided into conventional type (pressure: less than 4.0MPa) and high pressure type (pressure: more than 4.0MPa).

● The EEPROM memorizer is used and the measurement operation data storage and protection is safe and reliable.

● The international advanced microcontroller (MCU) and surface mounting technology (SMT) are used with reliable performance, high precision, low power dissipation, stable null point, Chinese menu and convenient parameter setting.

● It's with 4~20mA frequency and pulse output, alarm level output, RS485 communication interface and Hart and ModBus protocols. The special electromagnetic flowmeter system for thermal energy is integrated with thermal energy system components and calculations, a flow instrument and thermal energy integrating instrument with powerful function and suitable for heating system.

● The backlight display of instantaneous flow rate, cumulative flow (Σ+, Σ- and ΣD), flow velocity, flow percentage, empty tube ratio and flow state (excitation, flow and empty tube) by the high definition LCD is conducted.

● Protection grade: Integrated structure IP65 and split structure IP68.

● Explosive-proof grade: Exd II BT6 and intrinsically safe explosion proofing.

Execution standard

Execution standard | JB/T 9248~1999 | ||||

Nominal diameter | 10, 15, 20, 25, 32, 40, 50, 65, 80, 100, 125, 150, 200, 250, 300, 350, 400, 500, 600, 700, 800, 900, 1000, 1200, 1400, 1600, 1800, 2000, 2200, 2400, 2600, 2800 and 3000 | ||||

Peak flow rate | 15m/s | ||||

Accuracy | DNl5~DN600 | ±0.3% of indicating value: Flow velocity≥1m/s; ±3mm/s, flow velocity<1m/s | |||

DN700~DN3000 | ±0.5% of the indicated value, flow velocity>0.8m/S; ±4mm/s, flow velocity<0.8m/S | ||||

Fluid conductivity | ≥5uS/cm (customizable low conductivity type) | ||||

Nominal pressure | 4.0MPa | 1.6MPa | 1.0MPa | 0.6MPa | 6.3、10MPa |

DNl5~DN150 | DNl5~DN600 | DN200~DN1000 | DN700~DN3000 | Special ordering | |

Ambient temperature | Sensor | -25℃- +60℃ | |||

Converter and integrated type | -10℃- +60℃ | ||||

Lining material | Teflon, polychloroprene rubber, polyurethane, FEP F46 and screening PFA | ||||

Maximum fluid temperature | Integrated type | 70℃ | |||

Separated type | Polychloroprene rubber lining | 80℃; Indication at 120℃ when ordering goods | |||

Polyurethane lining | 80℃ | ||||

Teflon lining | 100℃; Indication at 150℃ when ordering goods | ||||

FEP F46 | |||||

Screening PFA | |||||

Lining material

Lining material | Main performance | Maximum medium temperature | Application scope | |

Body type | Separated type | |||

Teflon (F4) | It's a plastic whose chemical performance is the most stable and capable of resistance to boiling hydrochloric acid, sulfuric acid, nitric acid, aqua regia, concentrated alkaline and various organic solvents. It's not capable of resistance to corrosion of high velocity liquid fluorine, liquid oxygen and autologous oxygen. | 70℃ | Needing special ordering at 100℃ 150℃ | 1. Strong corrosive media (such as concentrated acid and alkali). 2. Health media. |

FEP (F46) | It's the same as F4, and the abrasive resistance and resistance to negative pressure surpass those of F4. | Same as above | ||

Polyvinyl fluoride (Fs) | The upper limit of applicable temperature is lower than that of teflon, but the cost is lower. | 80℃ | ||

Polychloroprene rubber | 1. Good elasticity, high breaking tenacity and good wear-resisting property. 2. It's capable of resistance to corrosion of general low concentration of acid, alkali and salt medium, but isn't capable of resistance to corrosion of oxidizing medium. | Needing special ordering at 80℃ 120℃ | Water, sewage and mud pulp with weak abrasiveness. | |

Polyurethane rubber | 1. Extremely strong wear-resisting property. | 80℃ | Pulp, coal slurry and mud with neutral strong wear | |

2. Poor corrosion resistance. | ||||

Electrode material

Electrode material | Corrosion resistance and wear resistance |

Stainless steel 0Crl8Nil2M02Ti | It's used for media with weak corrosivity (such as industrial water, domestic water and sewage) and applicable to the industrial sectors (such as petroleum, chemical engineering and steel) and fields (such as municipal administration and environmental protection). |

Hastelloy B | It is of good corrosion resistance against hydrochloric acid in all concentrations below the boiling point, capable of resistance to the corrosion of non-chloride acids and alkalis (such as sulfuric acid, phosphoric acid, hydrofluoric acid and organic acid) and nonoxidizing salt solution. |

Hastelloy C | It's capable of resistance to corrosion of nonoxidizing acids (such as nitric acid, mixed acid or mixed media of chromic acid and sulfuric acid, oxidizing salts (such as Fe or Cu) or substances containing other oxidants, such as hypochlorite solution above normal temperature and seawater. |

Titanium | It's capable of resistance to corrosion of seawater, various chlorides, hypochlorite and oxidizing acids (including fuming sulphuric acid, organic acid and alkali). It's not capable of resistance to corrosion of reducing acids (such as sulfuric acid and hydrochloric acid). However, when the acid contains oxidizing agents (such as nitric acid, Fc++ and Cu++), the corrosivity will greatly lower. |

Tantalum | It's of excellent corrosion resistance which is similar to that of glass. Except for hydrofluoric acid, fuming sulphuric acid and alkali, it's capable of resistance to the corrosion of almost all the chemical media (including hydrochloric acid and nitric acid at the boiling point and sulfuric acid below 150℃). In the alkali, anti-corrosion. |

Platinum/titanium alloy | It's capable of resistance to almost all the chemical media, but isn't applicable to aqua regia and ammonium salt. |

Stainless steel coated with tungsten carbide | Used for non-corrosive and highly abrasive medium. |

Note: Due to a wide variety of media, its corrosivity is influenced by temperature, concentration, flow rate and other complex factors, so the table is for reference only. The user should make their own choices according to the actual situation and carry out corrosion resistance test of material to be selected such as hanging test) if necessary. | |

Product model selection

FTE | Intelligent electromagnetic flowmeter | |||||||||||||

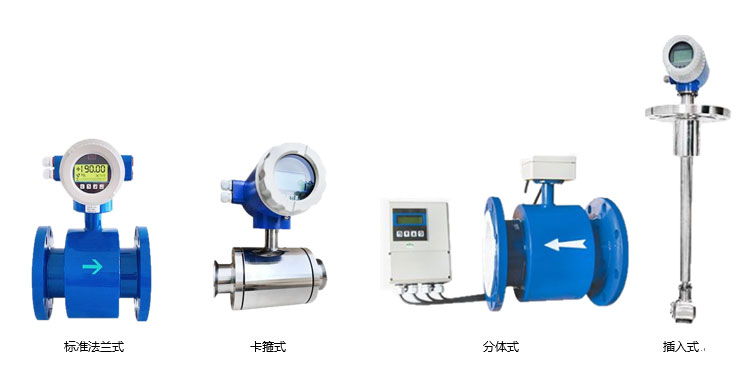

Electrode form: G Standard flange type C Clamp type V Plug-in type F Split type | ||||||||||||||

Electrode material 0 Stainless steel 1 Platinum (Pt) 2 Hastelloy B (HB) 3 Tantalum (Ta) 4 Titanium 5 Hastelloy C (HC) | ||||||||||||||

Lining material O Epoxy butane rubber W Polyurethane rubber E F4(PTFE) R F46(FEP) T F40(E-TFE) Y PO polypropylene U PPS polyphenylene sulfide | ||||||||||||||

Rated pressure (MPa) 4 DN10-80 1.6 DN100-150 1 DN200-1000 0.6 DN1100-2000 0.25 DN2200 | ||||||||||||||

Operating temperature E <80℃ H <180℃ | ||||||||||||||

Ground ring 0 Without ground ring 1 With ground ring | ||||||||||||||

Protection grade 0 IP65 1 IP68 | ||||||||||||||

Converter form 0 Integrated type 1 Split type | ||||||||||||||

Communication 0 None 1 RS-485 2 Hart 3 ModBus 4 PA bus 5 FF bus | ||||||||||||||

Enclosure material 0 Carbon steel 1 Stainless steel 2 Aluminium alloy | ||||||||||||||

Surface flange 0 Carbon steel 1 Stainless steel | ||||||||||||||

Mounting companion flange 0 Without 1 With | ||||||||||||||

Power supply 0 220VAC 1 24VDC(lour≥0.5A) | ||||||||||||||

Instrument range ***(1200 indicates the corresponding maximum flow: 1200㎡/h) | ||||||||||||||

FTE- | ||||||||||||||

QQ客服

QQ客服