Product overview

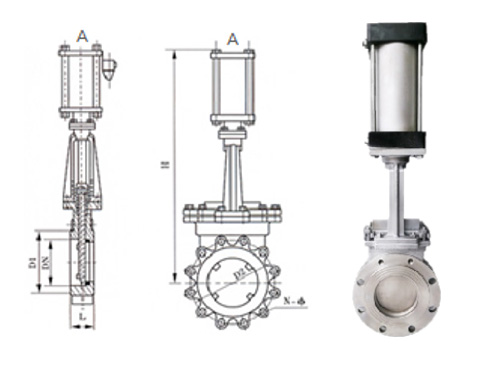

The VGP pneumatic knife-type brake valve is constituted by left/right valve, U-shaped sealing ring, flashboard, steel nut, valve rod, holder and air cylinder, and the valve opening and closing are performed by cylinder action. The motion control and signal output in the open/close position can be realized by the accessories (such as solenoid valve and proximity switch), and the automatic control of continuous action can be completed, too. The user can make a choice as per the actual demand. The cast iron, cast steel and stainless steel are used for the main body, and the diameter changes from DN50 to DN1000.

Product features

● The double-clip type structure is used with small volume and light weight;

● The completely open channel can be used to prevent the medium from being deposited in the valve;

● The newly developed U-shaped sealing ring can ensure the valve is of good leakproofness;

● The external seal of the flashboard is realized by the flexible sealing strip embedded into the valve, and the bolt and pressing plate can be used for adjustment;

● Small flow resistance;

● Convenient installation and repair.

Product application

The pneumatic sluice valve product is widely used for the fields (such as chemical engineering, coal, sugaring, sewage and papermaking) and is an ideal seal valve. It's especially suitable for regulating and throttling on the pipeline in the industries, such as papermaking, electric power and lithium battery new energy.

Product size

MPa | DN | L | D | D1 | D2 | H | N-M | A |

1.0 | 50 | 43 | 160 | 125 | 100 | 330 | 4-M16 | 180 |

65 | 46 | 180 | 145 | 120 | 360 | 4-M16 | 180 | |

80 | 46 | 195 | 160 | 135 | 390 | 4-M16 | 220 | |

100 | 52 | 215 | 180 | 155 | 440 | 8-M16 | 220 | |

125 | 56 | 245 | 210 | 185 | 510 | 8-M16 | 230 | |

150 | 56 | 280 | 240 | 210 | 600 | 8-M20 | 280 | |

200 | 60 | 335 | 295 | 265 | 700 | 8-M20 | 360 | |

250 | 68 | 390 | 350 | 320 | 840 | 12-M20 | 360 | |

300 | 78 | 440 | 400 | 368 | 960 | 12-M20 | 400 | |

350 | 78 | 500 | 460 | 428 | 1110 | 16-M20 | 400 | |

400 | 102 | 565 | 515 | 482 | 1250 | 16-M22 | 400 | |

450 | 114 | 615 | 565 | 532 | 1380 | 20-M22 | 530 | |

500 | 127 | 670 | 620 | 585 | 1530 | 20-M22 | 530 | |

600 | 154 | 780 | 725 | 685 | 1800 | 20-M27 | 600 | |

700 | 165 | 895 | 840 | 800 | 2150 | 24-M27 | 600 | |

800 | 190 | 1010 | 950 | 898 | 2420 | 24-M30 | 680 | |

900 | 203 | 1110 | 1050 | 1005 | 2680 | 28-M30 | 680 | |

1000 | 216 | 1220 | 1160 | 1115 | 3100 | 28-M30 | 700 | |

1200 | 254 | 1450 | 1380 | 1325 | 3450 | 32-M36 | 800 | |

1.6 | 50 | 43 | 160 | 125 | 99 | 330 | 4-M16 | 180 |

65 | 46 | 185 | 145 | 120 | 360 | 4-M16 | 180 | |

80 | 46 | 200 | 160 | 135 | 390 | 8-M16 | 220 | |

100 | 52 | 220 | 180 | 155 | 440 | 8-M16 | 220 | |

125 | 56 | 250 | 210 | 185 | 510 | 8-M16 | 230 | |

150 | 56 | 285 | 240 | 210 | 600 | 8-M20 | 280 | |

200 | 60 | 340 | 295 | 265 | 700 | 12-M20 | 360 | |

250 | 68 | 405 | 355 | 310 | 840 | 12-M22 | 360 | |

300 | 78 | 460 | 410 | 375 | 960 | 12-M22 | 400 | |

350 | 78 | 520 | 470 | 435 | 1110 | 16-M22 | 400 | |

400 | 102 | 580 | 525 | 485 | 1250 | 16-M27 | 400 | |

450 | 114 | 640 | 585 | 545 | 1380 | 20-M27 | 530 | |

500 | 127 | 715 | 650 | 609 | 1530 | 20-M30 | 530 | |

600 | 154 | 840 | 770 | 720 | 1800 | 20-M36 | 600 | |

700 | 165 | 910 | 840 | 788 | 2150 | 24-M36 | 600 | |

800 | 190 | 1025 | 950 | 898 | 2420 | 24-M36 | 680 | |

900 | 203 | 1125 | 1050 | 998 | 2680 | 28-M36 | 680 | |

1000 | 216 | 1255 | 1170 | 1110 | 3100 | 28-M42 | 700 | |

1200 | 254 | 1485 | 1390 | 1325 | 3450 |

Sluice valve material

Part name | Material name | Material grade |

Round nut | High-quality carbon steel | 25 |

Handwheel | Gray cast iron | HT200 |

Bearing gland | High-quality carbon steel | 35 |

Valve rod nut | Aluminum bronze | ZCuA19Mn2 and ZCuA19Fe4Ni4Mn2 |

Aluminium brass | ZCuZn25A16Fe3Mn3 | |

Bearing | — | 51110 |

Valve rod | Stainless steel | 304, 316 and 2Cr13 |

Bracket | Carbon steel and stainless steel | WCB, CF8, etc. |

Flashboard | Stainless steel | 304, 316, 304L, 316L and 2Cr13 |

Bolt and nut | High-quality carbon steel | 35 |

Packing gland | Carbon steel | WCB |

Packing | Flexible graphite packing, asbestos packing and enhanced teflon fiber packing | — |

Valve body | Carbon steel and stainless steel | WCB, CF8 (304), CF3 (304L), CF8M (316), CF3M (316L) and seal seat surfacing alloy or stainless steel |

Actuator parameter

Inner diameter of cylinder (mm) | Φ40 | Φ50 | Φ63 | Φ80 | Φ100 | Φ125 | Φ160 | Φ200 | Φ250 | |

Theoretical piston acting force (N) (subject to 0.4MPa operating pressure) | Thrusting force | 490 | 760 | 1215 | 1960 | 3077 | 4800 | 7869 | 12308 | 19227 |

Tension | 410 | 680 | 1030 | 1770 | 2675 | 4400 | 7379 | 10035 | 18463 | |

Working medium | Compressed air with oil mist after purification | |||||||||

Working pressure (MPa) | 0.15-1 | |||||||||

Ambient temperature (°C) | -10-+80 | |||||||||

Relative humidity | 95 | |||||||||

Piston speed (mm/g) | 50-500 | |||||||||

Durability (KM) | 600 | |||||||||

Design standard

Design standard | JB/T869l-1998 MSS SP-81 |

Flange standard | GB/T9113.1-2000 |

Structure length | GB/T1-5188.2-94 |

Test and pressure | GB/T13927-2000 |

Performance specification

Nominal pressure PN(MPa) | Shell test (MPa) | Seal test (MPa) | Applicable medium |

1.0 | 1.5 | 1.1 | Smoke, ash, slag and water mixture and air mixture |

1.6 | 2.4 | 1.8 |

QQ客服

QQ客服