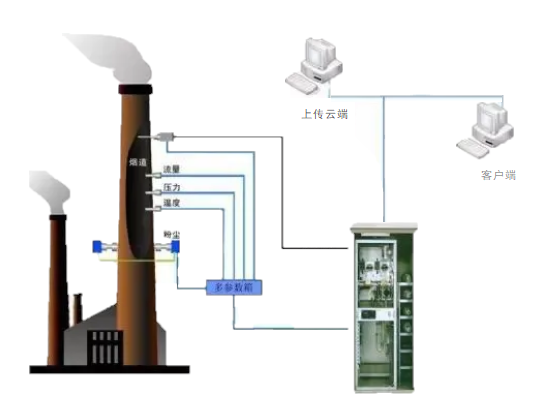

System introduction

The WLB flue gas emission continuous monitoring system (in-place type) consists of four parts (including smoke monitoring subsystem, gaseous pollutant monitoring subsystem, flue gas parameter monitoring subsystem and system control and data acquisition and processing subsystem). It can be used to monitor the parameters (such as SO2, NOx, O2, dust, temperature, pressure and flow velocity) in the gas, and for extended monitoring of such parameters as HCl, HF, CO, CO2 and humidity in the specific occasion. The measured gas is subject to dedusting by the sampling probe and directly enters the high-temperature gas analysis module (DOAS technology) for analysis and measurement. It's free from tracing pipe and condenser with quick response and effectively solves the technological problems (such as low measurement result arising from SO2 absorbed by the water precipitation based on the condensation method, and has a significant advantage especially in low concentration measurement occasions

System features

● The extraction condensation method is used and the extraction condensation method CEMS is capable of measuring SO2, NOx, 02, temperature, pressure, flow rate, humidity and dust;

● As for SO2 and NOx, the high-temperature tracing heat ultraviolet differential optical absorption spectroscopy (DOAS) analysis technology is used;

● The zirconia or electrochemical process is used for 02;

● The high temperature capacitance method is used for humidity;

● The thermistor (PT100), pressure sensor and pitot tube micro differential pressure method are used for temperature, pressure and flow rate, respectively;

● The laser backscattering method is used for dust;

● It has such advantages as accurate measurement, high reliability, low investment cost and quick response;

● Supporting online calibration, small measurement value fluctuation, high reliability and simple equipment.

● It has the advantages, such as convenient installation and commissioning and low requirement of site facilities.

● The whole machine is of compact structure with convenient transport and installation.

System parameters

●SO2: 0~50~1000ppm;

●O2: 0~25%;

●NOx: 0~50~1000ppm;

● Humidity: 0~40%;

● Dust: 0~10mg/m3 0~50mg/m3;

● Flow rate: 0~40m/s (customizable);

● Temperature: 0~300℃ (customizable);

● Pressure: -10kPa~+10kPa (customizable);

● Size: 580mm×290mm×1060mm;

● Tracing heat temperature: 120℃;

● Protection grade: Equipment cabinet: IP42, others: IP65;

● Power supply: 220VAC,2000W;

● Operating temperature: -10℃~+50℃;

● Operating humidity: 0~95%RH(no condensation)

● Compressed air requirements: (0.4~0.8)MPa,0.25m3/min; Clean, oil-free and water-free

Weight | About 150kg |

Measurement parameter | SO2, NOx, O2, temperature, pressure, flow rate, humidity and dust |

Heat tracing pipe temperature | 120C~200℃ |

Probe tracing heat temperature | 120℃~200℃ |

Protection grade | Equipment cabinet: IP42, others: IP65 |

Power supply | 220VAC,3000W |

Ambient temperature | -20℃~50°℃ |

Ambient humidity | 5%Rh~95%Rh (no condensation) |

External output | 4-20mA,RS232,RS485 |

Instruction case | 2000x800x800MM (height * depth * width) |

Blowback unit (compressed air source, blowback gas circuit and control valve) Pretreatment unit (sampling pump, dehumidification, fine filtration and drainage) Sampling unit (probe, filter and temperature controller) | |

System application

The WLB flue gas emission continuous monitoring system is used for real-time acquisition of various parameters (such as S02 concentration, N0x concentration, CO concentration, particulate matter concentration, oxygen content, temperature/humidity, pressure and flow rate). The industrial waste gas treatment equipment is used to promptly monitor whether the hazardous substance in the flue gas emitted by the enterprises exceeds standard and automatically transmit the real-time monitoring data to the superior department and is widely used for exhaust emission monitoring and process control of coal-fired power plant, garbage power plant, cement plant, glassworks, lime factory, ceramics factory, sintering, coke oven, desulfurization process and denitration technology.

QQ客服

QQ客服