Product overview

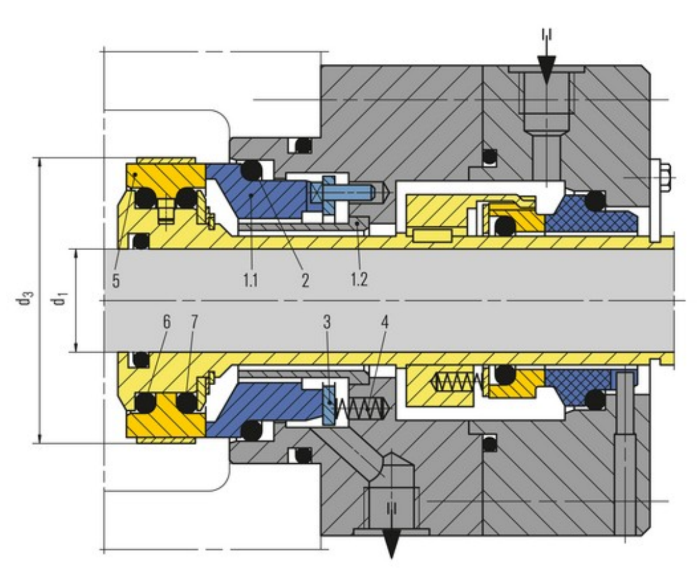

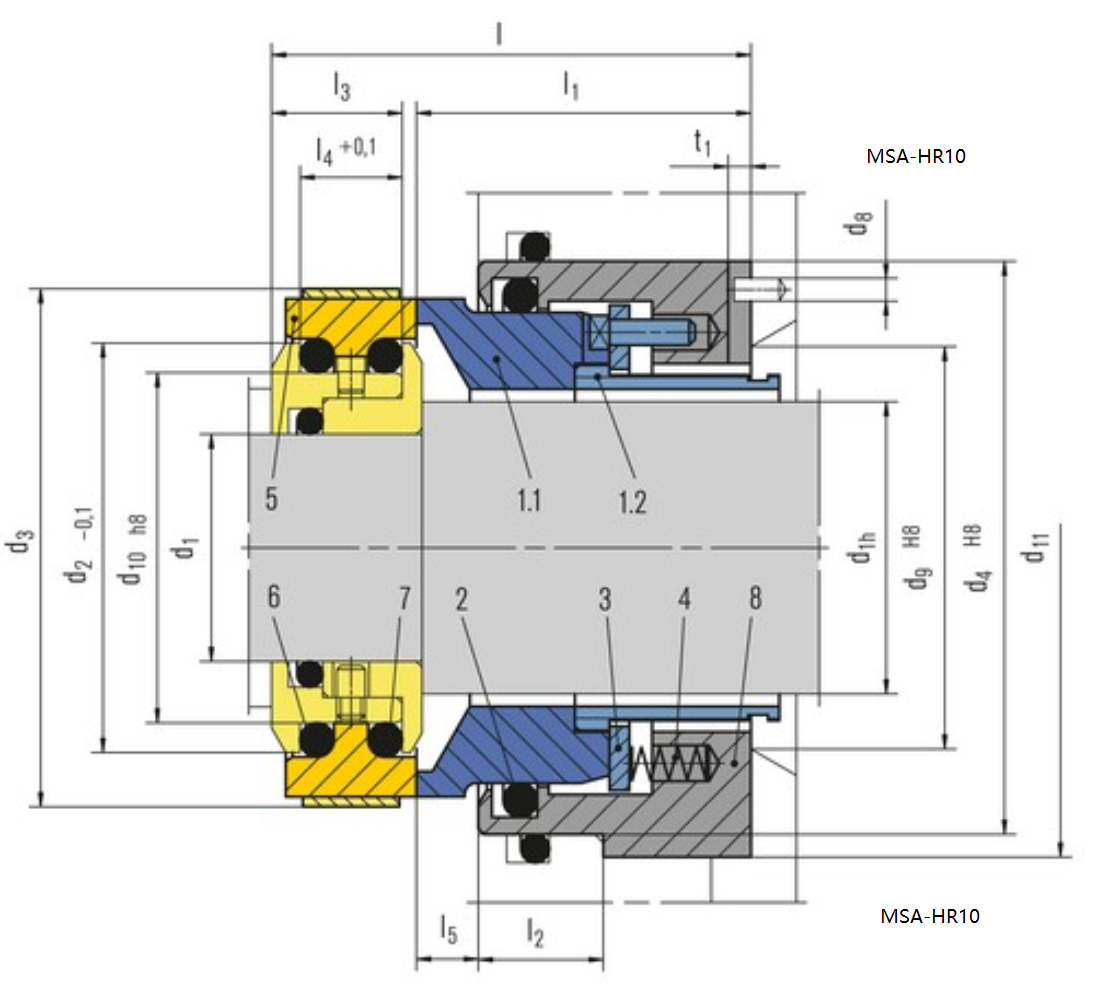

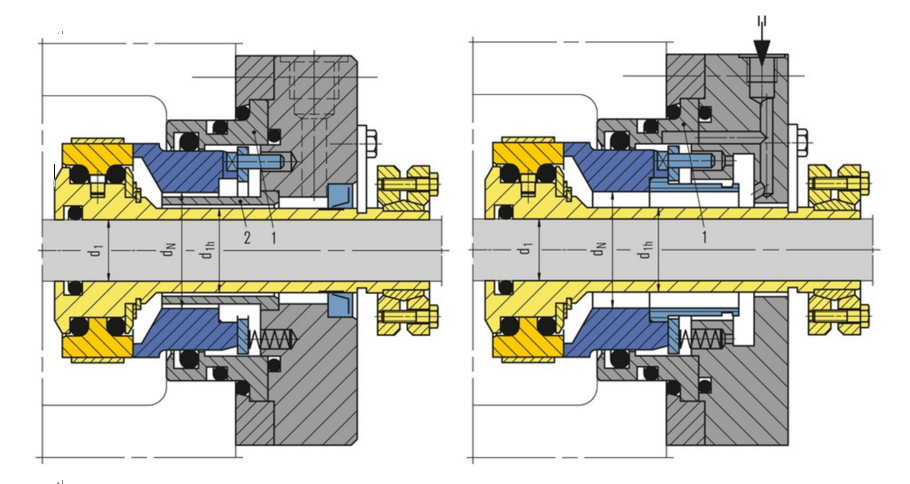

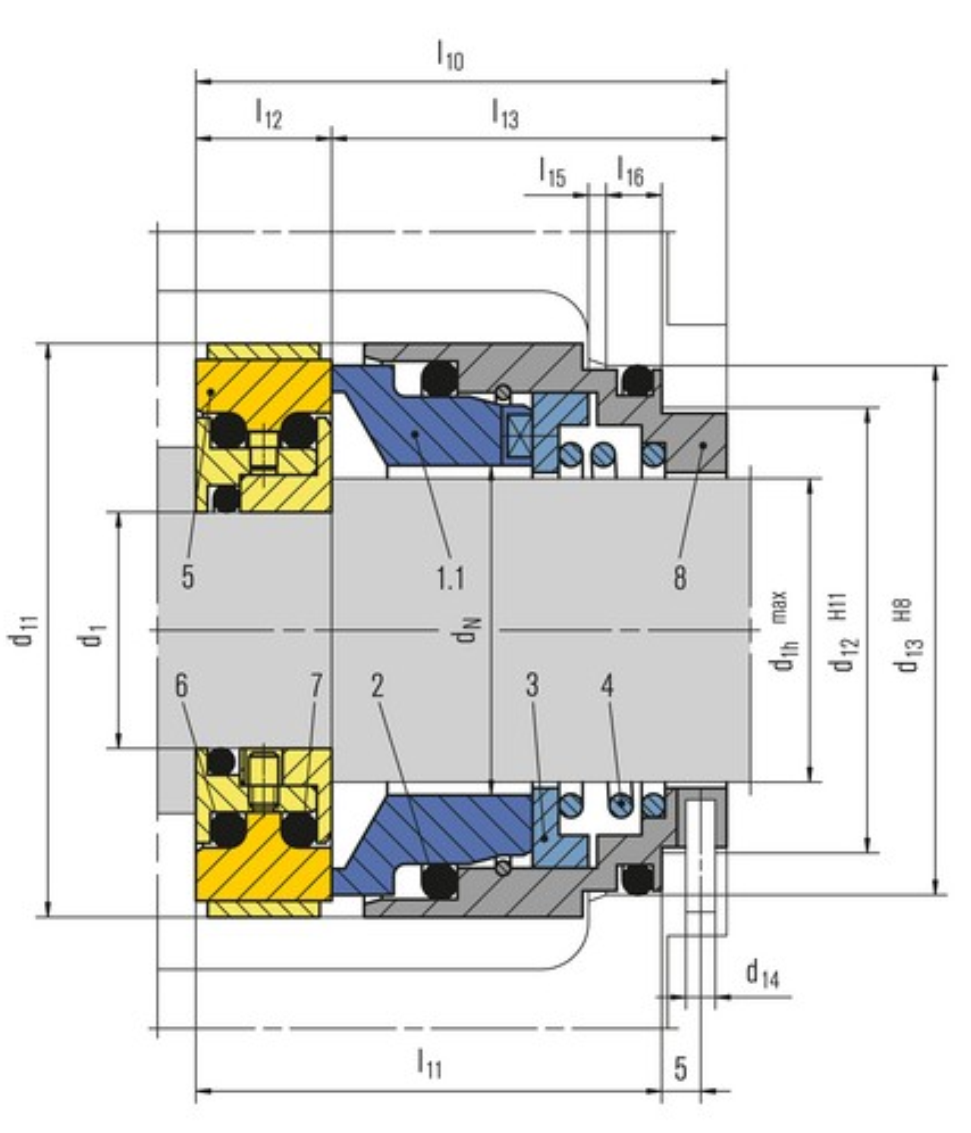

The structural style of the MSA waterless packaged mechanical seal is similar to that of external cooling packaged mechanical seal, with cooling rinse water and skeleton oil seal cancelled; Plenty of water resources and operating costs are saved. The structure characteristic of the mechanical seal is lubricating the sealing face completely by conveying sealing medium (size), and the concentration of solid particles in the medium determines the heat dissipation and wear of the sealing surface. To reduce the axial load, in addition to ensuring the necessary spring preloading, the balanced mechanical seal structure is used to reduce fluid action area, namely reducing the axial load which is the equilibrium ratio B (refer to ratio of fluid action area AS to sealing area Af) as the pressure of the sealing system increases. Therefore, the waterless packaged mechanical seal is of balanced structure, the end specific pressure and PV value of the sealing surface are reduced, and the sealing surface shall be close to the impeller as far as possible to avoid medium deposition around the sealing surface, resulting in mechanical seal failure; The seal chamber near the sealing surface is made into horn mouth form to facilitate medium flow and heat dissipation. The structure characteristics of the mechanical seal are as follows: Saving precious water resources. Due to very poor service environment of the mechanical seal, the special design of low spring specific pressure and sealing surface structure is used for the waterless packaged mechanical seal to meet the operating requirement of the mechanical seal. As for the seal chamber of the waterless packaged mechanical seal structure machinery seal, the evacuation and idle running without sealing medium are forbidden when the pump is running.

Product features

● Balanced structure;

● Cooling rinse water and skeleton oil seal are cancelled; Plenty of water resources and operating costs are saved;

● The balanced mechanical seal structure is used to reduce the fluid action area;

● The seal chamber near the sealing surface is made into horn mouth form to facilitate medium flow and heat dissipation;

● Sliding type optional position locking, easy installation and simple use and maintenance;

● Balanced type, arbitrary direction of turning;

● Forbidding the spring protection structure and strong anti-clogging ability;

● Small spring design, compact structure, uniform stress and wide serviceable range;

● No rinse water is needed, greatly saving water resources, the rinse water entering the process to form secondary evaporation is reduced, no circulating water discharge occurs, and the zero leakage control and environmental protection requirements are met;

● Multiple spring and single end face. The high-quality hard alloy and silicon carbide are used for sealing surface. SUS304, SUS316L, 2205 and 2507 can be chosen as the matrix material.

Product application

The spring outside avoids the contact between it and medium, the compensation ring is effectively protected, the spring can carry a large load without rotation, the working range of cavitation and evacuation spring is large which can withstand a great axial movement with simple and easy installation and the mechanical seal can be installed without seal chamber dismantled. It applies to the low-viscosity working conditions containing particles without cooling or cooling required. It's used for water and wastewater treatment technology sewage pump, pulp and paper-making industry, oil sand extraction, oil and gas industry flue gas desulfurization suspension pump and mining industry factory dirty, abrasive and solid-containing media.

Product specification

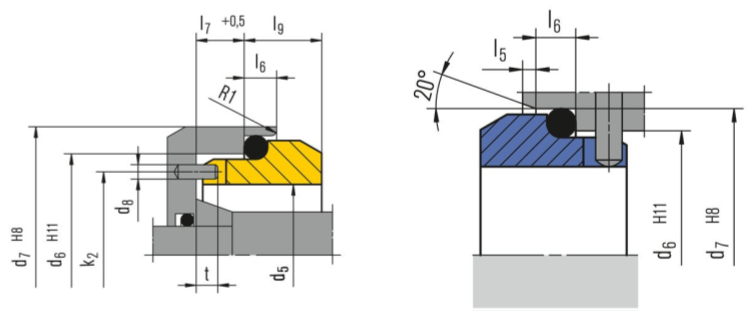

d1 | d1h | dN | d2 | d3 | d5 | d6 | d7 | d8 | d9 | d10 | d11 +0.2 min | l | l1 | l2 | l3 | l4 | l5 | l6 | l7 | l9 | k2 | t | t1 |

20 | 28 | 36 | 47 | 65 | 46 | 56.0 | 63.0 | 4 | 40 | 38 | 75 | 75 | 53 | 20 | 19.5 | 17 | 10.5 | 6 | 9 | 8.0 | 51.0 | 4.5 | 3 |

25 | 33 | 41 | 52 | 70 | 51 | 62.0 | 70.0 | 4 | 45 | 43 | 80 | 75 | 53 | 20 | 19.5 | 17 | 10.5 | 6 | 9 | 9.5 | 56.5 | 4.5 | 3 |

28 | 38 | 46 | 57 | 75 | 56 | 67.0 | 75.0 | 4 | 50 | 48 | 85 | 75 | 53 | 20 | 19.5 | 17 | 10.5 | 6 | 9 | 9.5 | 61.5 | 4.5 | 3 |

33 | 43 | 51 | 62 | 80 | 61 | 72.0 | 80.0 | 4 | 55 | 53 | 90 | 75 | 53 | 20 | 19.5 | 17 | 10.5 | 6 | 9 | 10.5 | 66.5 | 4.5 | 3 |

38 | 48 | 56 | 67 | 85 | 66 | 77.0 | 85.0 | 4 | 60 | 58 | 95 | 75 | 53 | 20 | 19.5 | 17 | 10.5 | 6 | 9 | 10.5 | 71.5 | 4.5 | 3 |

43 | 53 | 61 | 72 | 90 | 69 | 81.0 | 90.0 | 4 | 65 | 63 | 100 | 75 | 53 | 20 | 19.5 | 17 | 10.5 | 7 | 9 | 11.0 | 75.0 | 4.5 | 3 |

48 | 58 | 66 | 77 | 95 | 76 | 88.0 | 97.0 | 4 | 70 | 68 | 105 | 75 | 53 | 20 | 19.5 | 17 | 10.5 | 7 | 9 | 11.5 | 82.0 | 4.5 | 3 |

53 | 63 | 71 | 82 | 101 | 81 | 95.0 | 105.0 | 4 | 75 | 73 | 110 | 75 | 53 | 20 | 19.5 | 17 | 10.5 | 7 | 9 | 11.5 | 88.0 | 4.5 | 3 |

55 | 65 | 75 | 87 | 106 | 86 | 100.0 | 110.0 | 4 | 79 | 78 | 115 | 75 | 53 | 20 | 19.5 | 17 | 10.5 | 7 | 9 | 11.5 | 93.0 | 4.5 | 3 |

60 | 70 | 80 | 92 | 111 | 91 | 105.0 | 115.0 | 4 | 84 | 83 | 120 | 75 | 53 | 20 | 19.5 | 17 | 10.5 | 7 | 9 | 13.0 | 98.0 | 4.5 | 3 |

65 | 75 | 85 | 97 | 116 | 96 | 110.0 | 120.0 | 4 | 89 | 88 | 125 | 75 | 53 | 20 | 19.5 | 17 | 10.5 | 7 | 9 | 13.0 | 103.0 | 4.5 | 3 |

70 | 80 | 90 | 102 | 121 | 101 | 115.0 | 125.0 | 4 | 94 | 93 | 130 | 75 | 53 | 20 | 19.5 | 17 | 10.5 | 7 | 9 | 13.0 | 108.0 | 4.5 | 3 |

75 | 85 | 95 | 107 | 126 | 107 | 122.2 | 134.3 | 5 | 99 | 98 | 135 | 75 | 53 | 20 | 19.5 | 17 | 10.5 | 10 | 12 | 20.0 | 114.5 | 7.0 | 3 |

80 | 90 | 100 | 112 | 131 | 107 | 122.2 | 134.3 | 5 | 104 | 103 | 140 | 75 | 53 | 20 | 19.5 | 17 | 10.5 | 10 | 12 | 20.0 | 114.5 | 7.0 | 4 |

90 | 100 | 110 | 126 | 147 | 117 | 136.2 | 148.3 | 5 | 116 | 117 | 163 | 75 | 73 | 30 | 19.5 | 17 | 10.5 | 10 | 12 | 20.0 | 126.5 | 7.0 | 4 |

100 | 110 | 120 | 136 | 157 | 132 | 146.2 | 158.3 | 5 | 126 | 127 | 173 | 98 | 73 | 30 | 22.0 | 19 | 16.0 | 10 | 12 | 20.0 | 139.0 | 7.0 | 4 |

110 | 120 | 130 | 145 | 167 | 142 | 156.2 | 168.3 | 5 | 136 | 136 | 183 | 98 | 73 | 30 | 22.0 | 19 | 16.0 | 10 | 12 | 20.0 | 149.0 | 7.0 | 4 |

120 | 130 | 140 | 154 | 177 | 152 | 168.2 | 180.3 | 5 | 146 | 145 | 193 | 98 | 73 | 30 | 22.0 | 19 | 16.0 | 10 | 12 | 22.0 | 160.0 | 7.0 | 4 |

130 | 140 | 150 | 164 | 188 | 162 | 178.2 | 190.3 | 5 | 156 | 155 | 203 | 98 | 73 | 30 | 22.0 | 19 | 16.0 | 10 | 12 | 24.0 | 170.0 | 7.0 | 4 |

140 | 150 | 160 | 175 | 189 | 172 | 188.2 | 200.3 | 5 | 166 | 166 | 213 | 98 | 73 | 30 | 22.0 | 19 | 16.0 | 12 | 12 | 24.0 | 180.0 | 7.0 | 4 |

160 | 170 | 180 | 194 | 220 | 187 | 212.5 | 224.3 | 5 | 186 | 185 | 238 | 98 | 73 | 30 | 22.0 | 19 | 16.0 | 12 | 12 | 28.0 | 199.5 | 7.0 | 4 |

180 | 190 | 200 | 214 | 240 | --- | --- | --- | -- | 206 | 205 | 265 | 98 | 73 | 30 | 22.0 | 19 | 16.0 | -- | -- | --- | --- | --- | 4 |

190 | 200 | 210 | 232 | 255 | --- | --- | --- | -- | 218 | 220 | 280 | 115 | 83 | 30 | 28.4 | 25 | 19.0 | -- | -- | --- | ---- | -- | 5 |

200 | 210 | 220 | 242 | 265 | --- | --- | --- | -- | 228 | 230 | 290 | 115 | 83 | 40 | 28.4 | 25 | 19.0 | -- | -- | ---- | ---- | -- | 5 |

210 | 220 | 230 | 252 | 275 | --- | --- | --- | -- | 238 | 240 | 300 | 115 | 83 | 40 | 28.4 | 25 | 19.0 | -- | -- | --- | ---- | --- | 5 |

220 | 230 | 240 | 262 | 285 | --- | --- | --- | -- | 248 | 250 | 310 | 115 | 83 | 40 | 28.4 | 25 | 19.0 | -- | -- | -- | -- | -- | 5 |

230 | 240 | 250 | 272 | 295 | --- | --- | --- | -- | 258 | 260 | 320 | 115 | 83 | 40 | 28.4 | 25 | 19.0 | -- | -- | --- | ----- | -- | 5 |

250 | 260 | 270 | 292 | 315 | --- | --- | --- | -- | 278 | 280 | 340 | 115 | 83 | 40 | 28.4 | 25 | 19.0 | -- | -- | ---- | ---- | -- | 5 |

QQ客服

QQ客服